When you step on a scale in a South African medical clinic or weigh a parcel at a courier hub in Johannesburg, you likely expect an instant, perfect number to appear on the screen. However, many people face the frustration of getting different readings from the same scale within minutes, leading to confusion about whether the device is faulty or if the environment is to blame. Understanding the science behind your equipment helps you troubleshoot these inconsistencies and ensures you are getting the precision you paid for. At Scales4U, we believe that knowing how your digital scale works, from the metal sensors to the computer chips, allows you to maintain your equipment better and make smarter choices for your business or home.

What is a Digital Scale?

A digital scale is a type of weighing scale that uses electronic components to measure weight. Unlike traditional analog scales, which use mechanical parts such as springs and dials to measure weight, digital scales rely on technology to provide an accurate, easy-to-read digital output. These scales use sensors, usually strain gauges, to detect the force exerted by an object. The data is then processed electronically and displayed on a digital screen, making it simple to read the weight in units like kilograms, pounds, or grams.

Common Applications of Digital Scales:

- Retail and Commercial Use: Digital scales are widely used in retail settings, such as grocery stores, pharmacies, and post offices, where accurate weight measurements are essential.

- Medical and Healthcare: Hospitals and clinics rely on digital scales to measure patient weight accurately, especially for calculating dosage in drug prescriptions.

- Industrial Applications: Digital scales are used in warehouses, manufacturing, and logistics to weigh heavy loads with high precision.

- Laboratory and Research: For experiments and scientific research, precise weight measurements are crucial, and digital scales are used to ensure the highest accuracy.

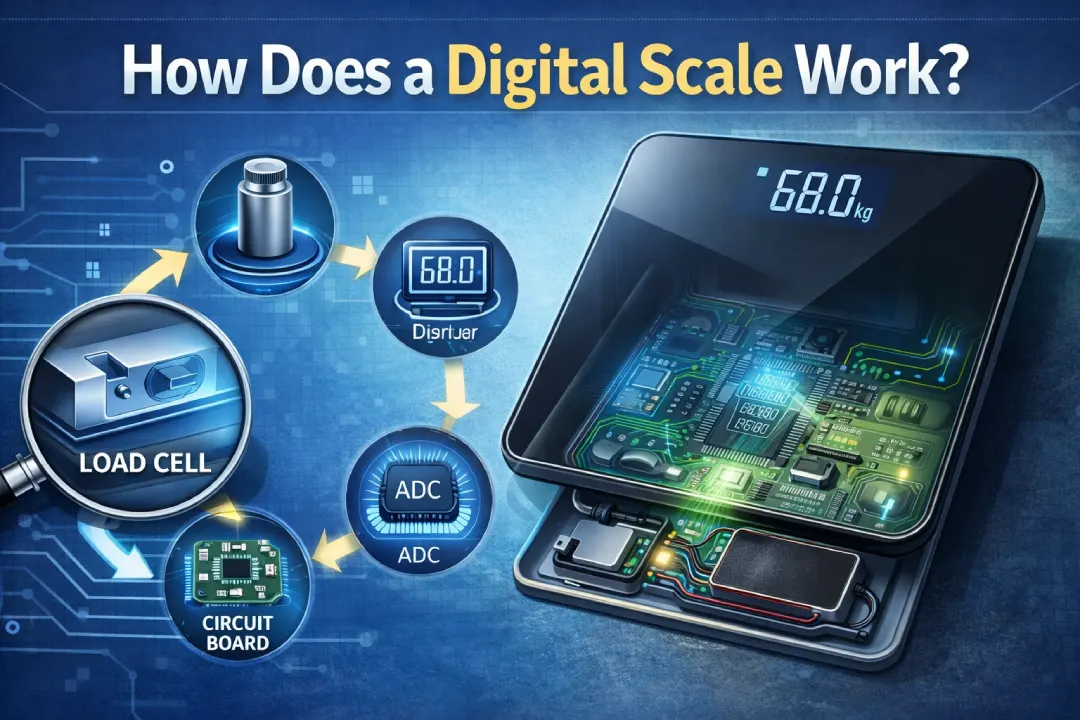

Key Components of a Digital Scale

To understand how a digital scale works, it’s important to know its key components:

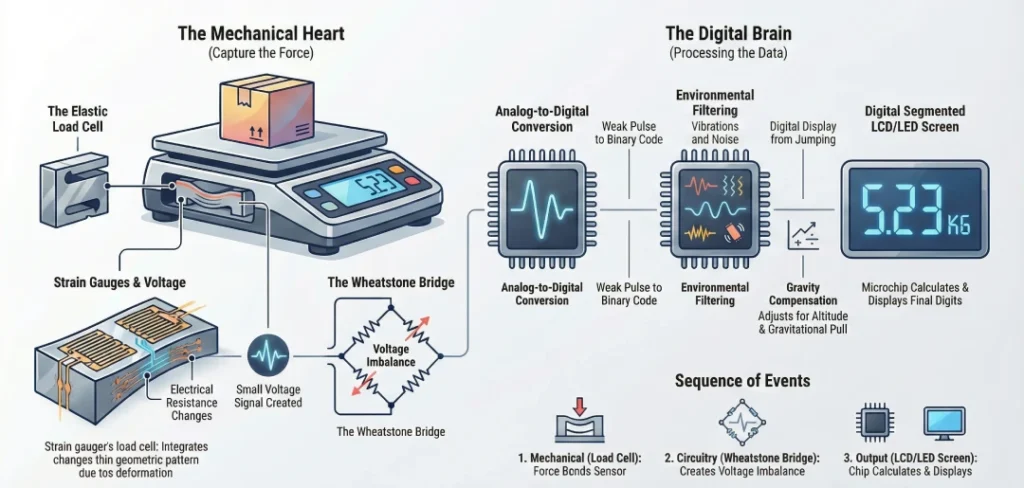

The Heart of the Machine: Understanding the Load Cell

The load cell is the most important part of any digital scale and is often referred to as the heart of the system. In most industrial and retail scales found across South Africa, this is a specially shaped block made of high-quality aluminum or stainless steel. This metal is chosen for its elastic properties, meaning it can bend slightly under weight and then snap back to its original shape perfectly once the weight is removed. If the load cell is made of cheap materials, it won’t return to its original shape, which is why some low-quality scales start giving drifting results after only a few months of use. The quality of this metal block determines the overall accuracy and the maximum capacity of the scale.

The Brain of the Sensor: Strain Gauges & The Wheatstone Bridge

While the load cell provides the structure, the strain gauges provide the data. A strain gauge is a tiny, flexible circuit glued onto the load cell. When the metal of the load cell bends even a fraction of a millimeter, the strain gauge stretches with it. This stretching changes the electrical resistance of the circuit. To make this change easy to measure, scales use a setup called a Wheatstone Bridge. This is a diamond-shaped circuit that balances four different sensors against each other. Even the smallest change in the shape of the load cell causes a bridge imbalance, creating a tiny electrical voltage. This voltage is the raw data that tells the scale exactly how much weight is being applied to the platform.

From Pulse to Numbers: The Digital Conversion Process

The electrical signal coming from the Wheatstone bridge is incredibly weak, often less than a few millivolts, which is far too small for a screen to display directly. To fix this, the scale uses a signal conditioner to amplify the pulse. Once the signal is strong enough, it passes through an Analog-to-Digital Converter (ADC). This chip takes the wavy electrical signal and chops it into binary code (1s and 0s) that a computer can understand. Finally, a microcontroller takes this data, subtracts the tare (the weight of any container), applies the local calibration settings, and sends the final result to the LCD or LED screen for you to read. The science behind accurate weighing involves more than just numbers; it requires a perfectly tuned circuit to translate force into binary code.

How Does a Digital Scale Work?

The process of weighing an object on a digital scale is straightforward but involves several steps to ensure accuracy:

- Placing the Object: When you place an object on the scale, the load is applied to the strain gauges, causing them to deform. This deformation is the first step in measuring the weight.

- Signal Conversion: As the strain gauges deform, they create a small change in electrical resistance. This change is passed to the load cell, where it is converted into a proportional electrical signal.

- Amplifying and Conditioning the Signal: The signal is then sent to a signal conditioner, which amplifies the weak signal from the load cell and filters any noise that could interfere with accurate measurement.

- Converting the Signal to Digital: The processed signal is then sent to the analog-to-digital converter (ADC), where the analog signal is converted into a digital one. This conversion allows the microcontroller to process the information more easily.

- Displaying the Result: Finally, the microcontroller sends the processed weight data to the scale’s display, typically an LCD or LED screen. You’ll see the weight of the object in your chosen unit, such as kilograms or pounds.

Weighing vs. Measuring: Weight vs. Mass in Digital Scales

It is a common mistake to think that a scale measures mass, but in reality, a digital scale measures the force of gravity pulling an object toward the earth. This is why the same scale might show a slightly different result if moved between high-altitude locations like Johannesburg and coastal cities like Durban. Because gravity is not perfectly uniform across the globe, high-precision digital scales often include gravity compensation software. This allows the microchip to adjust the calculation based on the local gravitational pull. When you use the Tare function on a scale from Scales4U, you are essentially telling the microcontroller to ignore a specific amount of force (like a container) so it only calculates the net weight of the goods inside. As defined by the International Bureau of Weights and Measures (BIPM), weight is a measure of the gravitational force acting on an object, which can vary slightly depending on your altitude and location.

Accuracy vs. Precision: What Really Influences the Reading?

In the world of professional weighing, accuracy and precision are two different things. Accuracy is how close the scale gets to the true weight, while precision is how consistently it can repeat that same result. Several factors can mess with these readings. For example, off-center loading occurs when an object is placed on the edge of the platform rather than the middle, causing the load cell to twist and give a false reading. Other issues include creep, where the metal sensor slightly deforms if a heavy weight is left on it for a long time, and radio frequency interference (RFI) from cell phones or two-way radios, which can scramble the tiny electrical signals inside the scale’s circuitry.

Modern Innovations: SAW and IoT Connectivity

As technology moves forward, we are seeing the rise of Surface Acoustic Wave (SAW) sensors, which use sound waves on a surface to measure displacement instead of traditional strain gauges. These are used for ultra-high-precision tasks in laboratories or high-end manufacturing. Additionally, the Internet of Things (IoT) has changed how South African businesses manage their data. Many modern digital scales now come with Wi-Fi or Bluetooth modules. This allows a warehouse manager in Cape Town to monitor stock levels in real-time on a tablet, as the scale automatically sends the weight data to a cloud-based server every time an item is weighed.

Why Your Scale Needs Regular Calibration

Because digital scales rely on the physical bending of metal and the flow of electricity, they are sensitive to change. Over time, the internal components can drift due to temperature changes or general wear and tear. Calibration is the process of comparing your scale’s reading against a known standard weight to reset the software’s accuracy. For businesses in South Africa, calibration isn’t just about getting the right number; it is often a legal requirement. Scales4U provides expert scale calibration services to ensure your equipment meets South African trade standards and prevents costly measurement errors

The Journey of a Measurement

To truly grasp how a scale works, it is helpful to visualize the split-second journey from the moment an object touches the platform to the moment the digits appear. This process is a relay race between mechanical parts and electronic processors. In a high-quality unit, this entire chain of events happens in less than half a second.

| Stage | Component Involved | Action Taken |

| Mechanical | Load Cell / Platform | Physical force causes the internal metal sensor to bend microscopically. |

| Electrical | Strain Gauges | The stretching of the foil gauges changes their electrical resistance. |

| Circuitry | Wheatstone Bridge | A tiny electrical voltage imbalance is created in the diamond-shaped circuit. |

| Processing | ADC & Microchip | The weak analog signal is amplified and converted into digital binary data. |

| Output | LCD/LED Screen | The microchip calculates the final weight and displays the human-readable digits. |

The Reliability of Modern Weighing

Digital technology has almost entirely replaced analog systems in South African industries because it removes the guesswork. While an analog scale might be good enough for some, the digital scale provides a level of certainty that is vital for pharmaceutical safety, retail fairness, and industrial logistics. By using high-grade load cells and advanced microcontrollers, modern scales can filter out vibrations and environmental noise that would make an analog needle jump uncontrollably. As long as the scale is used on a flat, stable surface and kept within its intended weight capacity, it remains the most reliable tool for any weighing task.

Frequently Asked Questions

Why is my digital scale giving different readings for the same object?

The most common reason for inconsistent readings is an unstable surface. If the scale is on a carpet or an uneven floor, the load cell cannot measure the vertical force of gravity correctly. Additionally, low battery power can cause the Analog-to-Digital Converter to struggle, leading to fluctuating numbers.

Can a digital scale be repaired if it stops working?

Yes, in many cases. If the screen is blank, it may be a simple power or wiring issue. However, if the scale provides wildly incorrect weights, the load cell may have been shock loaded (hit with a heavy force too quickly). At Scales4U, we specialize in diagnosing these faults and replacing damaged sensors to restore your equipment to factory standards.

Do digital scales work in the cold?

Extreme temperatures can affect the electrical resistance in the strain gauges. High-quality scales include temperature compensation circuits to handle South African weather variations, but it is always best to let a scale warm up for a minute in very cold environments to allow the electronics to stabilize.

How do smart scales measure body fat?

Many digital health scales use a method called Bioelectric Impedance Analysis. They send a very weak, unnoticeable electrical current through your feet. Since fat, muscle, and water conduct electricity differently, the scale’s microchip can estimate your body composition based on how much the current is slowed down.

How do I know if my scale is accurate?

The only way to be certain is to use a certified calibration weight. If you weigh a 5kg standard weight and the scale shows 5.05kg, your scale has drifted. For commercial businesses, this check should be performed regularly by professionals to ensure your Legal for Trade status remains valid.